To travel by balloon, you may be thinking of types of balloons and what a balloon engine is.

The envelope, basket, and burner system are the three components of a hot air balloon.

A hot air balloon burner is a rather simple piece of technology, and when compared to other planes, it’s reasonably inexpensive for what it delivers.

The burner is the hot air balloon’s engine. It’s what forces the heated air into the envelope, causing the balloon to lift.

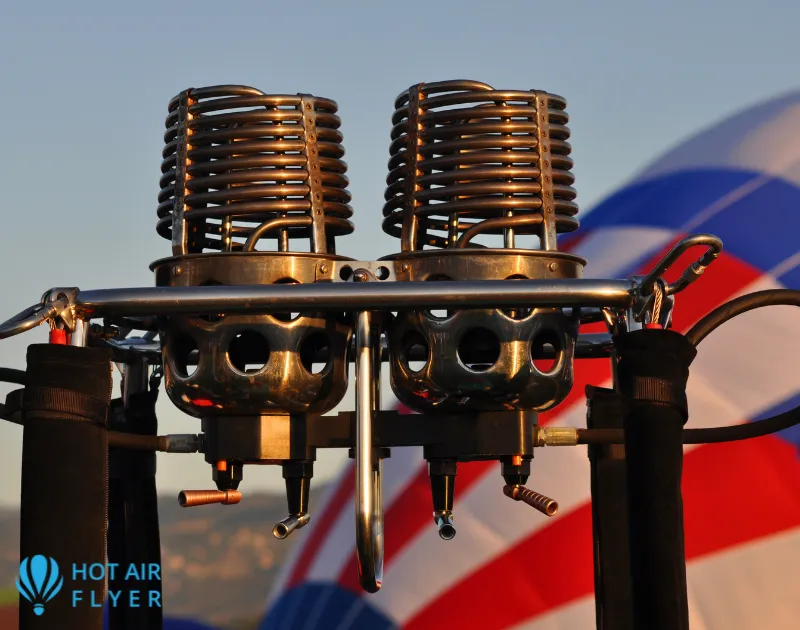

Depending on the size of the balloon flying, there are many different types of burners available, including single, double, and quad systems.

The Operation of the Burner

Modern hot air balloons heat the air with propane in the burner. Very strong, load-bearing tapes run vertically along the seams between the throat and crown of the envelope to connect ropes from the burner assembly to the envelope above.

In the cylinders, propane is compressed to a high pressure and then dispensed as a liquid to the burner. The propane goes to the burner and is ignited by a pilot light when the pilot starts it up.

As the flame burns, the metal in the surrounding tubing warms up, and when the tubing heats up, the propane flowing through it heats up as well.

The Different Types of Burner Systems

The twin burner is the most popular, as it has two burner coils. A single burner can power a balloon, but the envelope’s size must be taken into account. On smaller balloons with 1 or 2 passengers, a single system is usually sufficient.

How Does the Burner Work?

Normally, the burner or burners are aimed straight into the balloon envelope’s center. A pilot light, similar to those seen on regular gas burners, ensures quick access to heat anytime it is required.

A blast valve allows the pilot to control the pace at which gasoline is released from the tanks.The pilot merely presses the trigger on his blast valve to suck gasoline into the burner. The pilot light ignites the liquid propane gas as it travels under pressure from the fuel tank to the burner.

This pressure is shown via a pressure gauge on the burner. The propane is delivered from the basket’s tanks to the burner system through a flexible pipe. On the burner, the fuel passes through coils that evaporate the liquid gas.

The pilot light then ignites the vapor, shooting a six- to eight-foot flame into the envelope, producing a loud whooshing sound and adding 12 million BTU’s (British Thermal Units) per hour of heat. The amount of heat required to raise the temperature of one pound of water by one degree Fahrenheit is measured in BTU’s.

Burner Output

To give you a better idea of how powerful a burner system in a hot air balloon may be, one burner produces enough heat per hour to comfortably heat 120 three-bedroom homes.

Propane, which is almost solely used in hot air ballooning, also has the benefit of being easily available and relatively inexpensive in today’s energy-scarce world.

It is a by-product of the petroleum-manufacturing process and is also known as liquefied petroleum gas, or LPG.

Because propane is odorless, refineries added a chemical called Mercaptan to the gas as a safety measure. Mercaptan has a strong, sweetish odor, making gas leaks easy to spot.

Fuel tanks, either ten-gallon aluminum or twenty-gallon stainless-steel, are used to store propane.

The more expensive stainless-steel tank has the advantage of being lighter, allowing you to carry more fuel with less tank weight.

The Envelope

The section of the plane that resembles a balloon is known as an envelope.

It’s also known lovingly as “the bag” by some pilots.

Stainless steel suspension wires connect it to the gondola, or basket, in which the pilot and passengers ride.

The envelope is made of ripstop, fire-resistant nylon, comparable to what hikers and mountaineers use in their backpacks or lightweight tents.

A polyurethane coating is applied to the envelope to reduce porosity, and a UV inhibitor is included in the coating to assist the fabric withstand the sun’s rays.

The balloon’s top cap or crown can be designed in one of two ways. A circular deflation port is closed off by a round panel, which is maintained closed during flight by a flexible hook and loop closure.

A deflation port line, often known as the rip line and colored red, runs from the top to the basket and is pulled by the pilot upon landing to deflate the envelope instantly.

When you pull on the line, the hook-and-loop closure opens, allowing the heated air to escape.

Temperature indicators known as telltales are attached to the interior of the balloon envelope at the top or crown.

When placed, these telltales are white, but when the air inside the envelope reaches a certain temperature, they become black.

This allows the pilot to see when his balloon may need to be repaired at a look.

The cubic capacity of an envelope determines the number of people who can be safely taken aloft in a balloon.

However, depending on other conditions, such as air temperature and altitude, its capacity may be altered upward or downward.

Heating The Envelope

The air inside the envelope can be heated in two ways. One method is to open the blast valve, which, when fully open, may add heat at a rate of 12 million BTU’s per hour.

Intermittent blasts throughout flight allow the pilot to maintain a consistent temperature in the balloon, which in turn offers a consistent height during the trip.

The “cruise” or metering valve is the second way of adding heat to the envelope.

You can maintain a continuous output from the burner, which will produce a standard temperature, by monitoring the exact flow of propane to the burner. This would allow you to fly straight and level without needing to use the blast valve as frequently.

In a hot air balloon, it’s as near as you can get to flying on autopilot.

I’m Annie, a twenty-something year old girl who loves hot air balloons. So much so, that I have a full time job as a Flight Instructor and it is all I love talking about. Something about being up there in the elevated altitudes helps all my stresses float away!